Cobalt Based Alloy Stellite Valve Casting

Cobalt Based Alloy Castings Fulfill High Demanding Applications

At Teamco, we understand the critical importance of high-performance materials in valve applications, Cobalt Based Alloy Stellite valve castings are our high-quality OEM valve casting solutions, tailored to meet the precise demands of customers’ industries. Alloy 6 and 12 are two of the most trusted Cobalt-Chromium Alloys known for their exceptional wear resistance, corrosion resistance, and high-temperature stability. With years of expertise, we’re proud to offer OEM casting services that deliver unparalleled durability and performance. Whether you need valve parts for extreme environments or heavy-duty industrial applications, our Stellite-enhanced metal castings ensure long-lasting reliability and superior strength.

Cobalt Based Alloy, commonly known by the brand name Stellite, are a family of high performance alloys primarily composed of cobalt combined with chromium and other elements such as tungsten, carbon, and nickel. Teamco provides API 6A valve castings, such as cage and wear sleeve of the choke valves, in these alloys highly valued for their exceptional strength, wear resistance, corrosion resistance, and high-temperature stability, making them ideal for applications in demanding environments. By knowing the material feature of versatility, Teamco has the capability to fine-tune properties of cobalt-based alloys for specific applications in industries such as aerospace and energy.

Key Characteristics of Cobalt Based Alloy (Stellite):

1. Wear Resistance: Cobalt-based alloys are incredibly durable and resistant to wear, abrasion, and mechanical stress, which is why they are widely used in cutting tools, valve seats, and other components that undergo constant friction and mechanical strain.

2. Corrosion Resistance: Thanks to their high chromium content, cobalt-based alloys exhibit excellent resistance to corrosion, particularly in aggressive environments such as acids, seawater, or high-temperature steam, making them suitable for chemical processing, marine, and other harsh environments.

3. High-Temperature Stability: These alloys maintain their strength and resist oxidation at elevated temperatures. This makes them ideal for components exposed to extreme heat, such as turbine blades and aerospace parts.

4. Hardness and Toughness: The alloy is extremely hard, which makes it effective for use in wear-resistant coatings and cutting tools. Despite its hardness, it remains tough and resistant to cracking, ensuring long-lasting performance in critical applications.

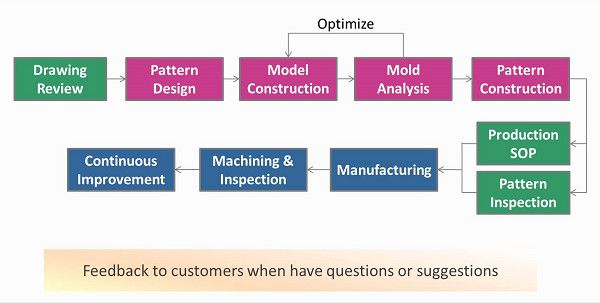

Pattern Optimization:

To eliminate casting trials and improve casting quality, Teamco utilizes process simulation tool which allows Teamco find the best counterpoise between casting quality and the production costs before creating physical prototypes for customers. From tooling die design, creations of wax and shell molds, metal liquid pouring, heat treatment and sand blasting, to QC inspection then the final casting, multiple variants determine to the casting quality. Teamco has experienced teams work closely with customer from the first stage when receive customers’ drawings. Adequate communications bring to satisfied customers.

Tooling design optimization brings to product quality.

Can Teamco Customize your Cobalt-Based Stellite Castings?

Yes, Teamco can customize your Stellite castings to meet your specific designs or performance requirements.

1. Customized Materials for Your Specific Needs

We understand that the right material is key to performance of your parts. We can tailor the alloy compositions to match your exact specifications and desired mechanical properties, such as wear/ corrosion resistance and high-temperature performance based on your applications.

2. Collaborative Design Support

With expertise, we work directly with customers from beginning. For intricate designs that require high accuracy and a smooth surface and when part sizes fit, investment casting will be selected to create the high quality parts. Through implementing the simulation tool and comprehensive communications with customers, the castings will be produced by the optimized patterns. This collaborative approach leads to stable and long-term partnership.

3. Precision Machining for Perfect Fit

After finishing the castings, we provide CNC machining to fine-tune parts to meet exact specifications. To have smooth surface, we provide grinding and polishing. If you have demand of parts assembly, Teamco is capable of providing threading and tapping for sub-assembly. These procedures make sure your parts are not only functional but also ready for seamless integration into your products or system.

4. Heat Treatment and Surface Treatment to Enhance Durability

Specific heat treatment processes such as annealing or quenching enhance the mechanical properties of castings. To achieve required appearance and durability, we provide nitriding, shot peening, plating or coating to strengthen surface hardness or performance of corrosion-resistance.

5. Rigorous Quality Control to Let Customers Satisfied

We have comprehensive quality control process, material testing on strength and hardness ensures parts performance as expected, dimensional accuracy let parts meet needed measurements and non-destructive testing to check for internal defects and ensure structural integrity. With our rigorous quality control, customers can trust that every part will meet the highest standards, giving them confidence in such product development.

Main Cobalt Based Alloys Teamco Cast:

| Co Alloy | Co % | Cr % | W % | C % | Hardness |

|---|---|---|---|---|---|

| Alloy #3 | Base | 30.5 | 12.5 | 2~3 | 48~63 HRC |

| Alloy #6 | Base | 27~35 | 3~6 | 0.9~1.4 | 36~45 HRC |

| Alloy #12 | Base | 27~32 | 7.5~9.5 | 1.4~2.0 | 45~51 HRC |

Applications

- Energy

- Chemical Industry

- Mechanical Industry

- Automotive

- Aerospace

Purchase Information

- L/T (Lead Time for Samples and Mass Production): please confirm with contact sales for the best shipping schedule.

- MOQ (Minimum Order Quantity): depending on design and specifications (to be confirmed)

- MTR (Material Test Report): Mill Certificate + Inspection Report + Others Per Customer’s Requests (to be confirmed)

- Shipping Term: FOB

- For specific custom requirements such as special designs, inspection standards or materials, please contact our sales representatives for further details.

Cobalt Based Alloy Stellite Valve Casting | Advanced Grease Fittings and Valve Accessories: Ensuring Reliability Under Pressure

Located in Taiwan since 1995, Teamco Industries Corporation specializes in manufacturing Cobalt Based Alloy Stellite Valve Casting, precision machined valve components, custom metal parts for sensors and controls, high-pressure grease fittings and valve accessories, stainless steel and alloy-based parts for various industrial applications and comprehensive assembly services for cable and wiring harnesses. Discover top-tier precision machined valve components tailored for demanding industrial applications. Teamco specializes in custom solutions for oil, gas, and beyond, ensuring unparalleled quality and performance.

Teamco is a leading manufacturer specializing in high-quality machined metal parts, catering to critical industries like Oil & Gas. With a focus on precision and reliability, our product range includes CF8M Casting Ball Valve Parts, Stainless Steel Machined Valve Components, and High Pressure Grease Fittings, among others. Our commitment to excellence is backed by robust OEM capabilities and a comprehensive approach to metal parts assembly, ensuring top-tier performance and durability for industrial and marine applications.

Teamco has been offering customers high-pressure grease fittings and valve accessories to clients, both with advanced technology and 30 years of experience, Teamco ensures each customer's demands are met.