Company Overview

Welcome to Teamco – Delivering Custom Solutions with Unwavering Commitment

With a corporate mission of providing customers with the most competitive solutions for customers of industrial segments, Teamco has been providing stable quality OEM machined valve metal parts tailored to meet customers' specific needs in various segments. Established in 1995, Teamco started from a casting foundry based in valve metal parts and marine hardware; its main manufacturing facilities are located in Taiwan. We deliver consistent quality products to worldwide customers in industries of Oil & Gas, Fluid Control, Sensing and Measuring Equipment, Machinery, Heavy Duty Building Locking Components, and Marine Metal Hardware. To comply with higher mechanical properties, Teamco also built up forging capability. To satisfy the customer’s high precision tolerances required in assembly, we have a precision machining team, ensuring parts are machined according to the customer’s drawings. Our major materials are stainless steel, carbon steel, and alloys. With wide experience in fulfilling customers’ diversified requirements and international standards, we are dedicated to serving customers with metal parts designed for demanding environments, such as metal-to-metal valve parts and cobalt-based alloy castings. We are here to solve customers’ problems and to be a reliable partner of metal parts solutions.

Teamco consistently delivers competitive solutions by seamlessly integrating supply chain resources to meet diverse demands. With a commitment to enhancing our manufacturing capabilities, our high-quality services and solutions have earned the endorsement of globally recognized brands. We excel in production, machining, quality inspection, parts assembly, and various industry applications. Our dedicated teams—including sales, engineering, quality assurance, and customer service—collaborate closely with our clients, ensuring we fully understand their needs and are committed to transforming their visions into reality.

Teamco is Taiwan's leading manufacturer of custom Valve Grease Fittings and Valve Wave Springs for the Oil and Gas industry, committed to innovation and quality

Teamco is the first valve parts manufacturer in Taiwan who has full production lines of high temperature/ high pressure Valve Grease Fittings and Valve Wave Springs used in Oil & Gas industry. Starting from the founding business of machined castings, Teamco has expanded capability to comprehensive valve parts, include body, cap, ball, stem, seat, bonnet, shaft, handle, plate, grease fittings and wave springs, etc. Our professional engineering and machining teams keep enhancing the machining capability for satisfying more diversified customer requests. We’ve expanded our product applications to Energy, Oil & Gas Pipe Line Valves Repair and Maintenance, Industrial Fluid Control, Food & Drinks Processing, Automation Sensor Metal Parts, Mechanical Equipment, High Security Locks, Marine Equipment, etc. Our vision is to perform as the quality OEM solution partner. We cooperate with customers with mutual trust to achieve "Win-Win", with what delivered beyond what we commit.

Teamco – Taiwan’s First Manufacturer Provides Both Metal Parts Services And Cable Assembly Services For Segments Of Valve Actuation And Industrial Process Control

To extend our service scale to fulfill customers’ requests, Teamco integrates strategic partnership into the cable assembly services for industrial customers. In Taiwan, Teamco is the first supplier provides OEM services in both metal parts and cable assembly. Our core capability is to solve customers’ problems and then bring more values and benefits to customers. Through cooperating with major connector partners include Amphenol, Delphi, JAE, Molex and TE, etc., Teamco has successfully expanded our service area to valve automation control, industrial fluid control, production process control, instrumentation equipment, Telecommunication and sensor devices. Teamco has been dedicating us as the trustworthy partner of worldwide industrial customers.

Leadership

For more than 20 years, Teamco has been innovating in our production capability and enhancing our competitive advantages in metal parts integration, especially on valve components. It is our commitment that makes us the most trustworthy partner of our clients. It is our responsibility that makes us the most capable supplier to fulfill the customer requirements.

We believe that the employees are the biggest assets of the company. Professional training and knowledge management have been continuously our important tasks every year. We apply ourselves to being a company that not only emphasizes our partner needs but also takes care of our employee and their families. It is the virtual Teamco culture that determines our competitiveness in serving OEM services with professionals.

CEO - Ray Jen

Teamco is a dedicated service provider focused on meeting customer needs. We invest in our employees' skills to create professional teams that engage with clients and deliver tailored solutions. Our sales, engineering, quality assurance (QA), production, and support teams work collaboratively to prioritize customer satisfaction. We are committed to quality management in line with customer specifications and international standards, which is crucial for building trust. By offering customized services, we effectively address our customers' unique challenges. Our goal is to continuously elevate our service levels and foster mutual growth with our clients.

Milestone

Escalating capability to Achieve Customer Satisfaction.

1995 ~ 2014: Core Capability

- Founded in 1995

- Started from a casting foundry

- Served from Oil & Gas industry and metal hardware

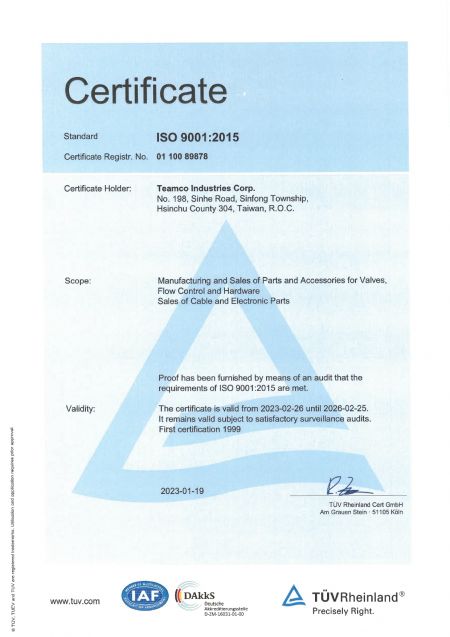

- ISO9001 quality management certified

- Expanded to forgings and bar stock machining parts

- Provide comprehensive valve parts and accessories

- Major in Stainless Steel and Carbon Steel

- Provide high precision building and marine hardware

2015 ~ 2022: Product Diversification

- Provide valve assembly parts: grease fittings and wave springs

- New application in higher precision: fluid control metal parts

- New application in industrial sub-assembly, capable of ODM reverse-engineering

- Expand to Alloys of Inconel 625, 718, X-750

- Total solution to assigned heat treatment and surface treatment

- New service: cable assembly (valve automation and instrumentation)

- Diversified customer areas: America, Europe, Mid-East, Asia, Asia-Pacific and Africa

2023 ~: Business Expansion

- Grease fittings are sold to oil & gas pipe line valve repair and maintenance worldwide

- Wave springs are sold to more assemblies, oil & gas, optical device, medical equipment and semi-conductor machine.

- Engineering-driven capability to parts in more material types and production methods

- OEM valve metal parts in super alloys used in demanding applications

- ISO Certificate

- Basic Information

Establishment Apr., 1995 Founder Simpson Jian Capital USD5 million Employees 200 people worldwide Quality Certification ISO9001: 2015 Certified Main Markets Australia, Canada, Germany, Indonesia, Italy, Japan, Malaysia, Russia, Saudi Arabia, Swiss, UK, etc. Specialty - Total solution of custom metal parts production, machining, surface finish and industry inspections

- OEM service of industrial cable assembly solutionsMain Applications Oil & Gas Valve Parts, Pipe Line Valves Repair and Maintenance, Industrial Process Control, Fluid Control Metal Parts, Sensor and Measuring Metal Parts, High Security Locking Components and Building Hardware, Marine Hardware Headquarter HsinChu, Taiwan Manufacturing Sites Taiwan, China