Quality Control

Product Quality is High Priority

Teamco has consistently offered the foundry segment's excellent technologies and custom service to the customers. We have built remarkable reputation and become a very reliable source of precision machining parts for valve and flow control parts, mechanical components and other metal hardware. Teamco is ISO 9001: 2015 certified and we have comprehensive inspection equipment. List is shown as below. All our chain members execute the same control procedures and management system.

Quality Control

We are ISO certified. All our management and productions are strictly monitored under ISO9001:2015 management achieve requirements of industry standards. Here is list of our in-house inspection equipment.

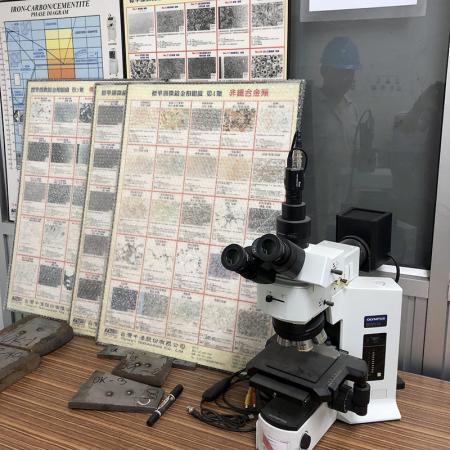

| Material Analysis: | ● Spectrometer ● Metallographic Microscope |

|---|---|

| General Inspections: | ● Calipers ● Height Test Machine ● 3-D Measuring Machine |

| Partial Dimensions: | ● Contour Measuring Machine ● Optical Projector ● 2.5-D Projector |

| Surface Roughness: | ● Surface Roughness Tester |

| Mechanical Properties: | ● Rockwell Hardness Tester ● Brinell Hardness Tester ● Universal Tensile Test Machine ● Universal Impact Test Machine ● LNG Cryogenic Tester (-196°C) |

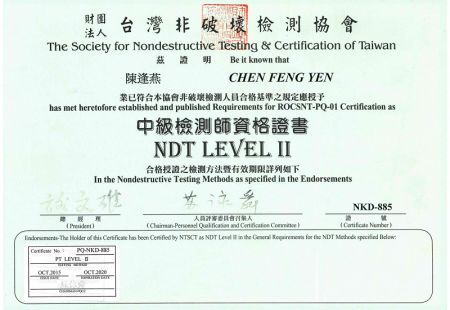

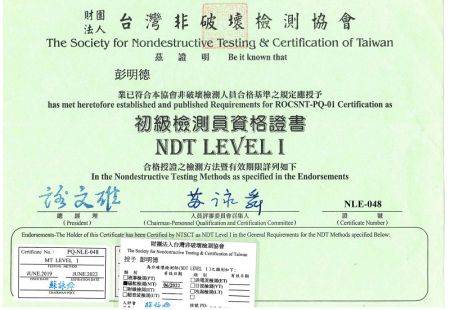

| Non-Destructive Tests (NDT): | ● Ultrasonic Testing Equipment (UT) ● Magnetic Particle Inspection Tester (MT) ● Penetrant Inspection Equipment (PT) |

| Leakage: | ● Air Leak Tester |

| Corrosion Resistant: | ● Salt Spray Test Machine |

- Spectrometer

- Metallographic Microscope

- Brinell & Rockwell Hardness Testers

- Universal Tensile Test Machine

- Universal Impact Test Machine

- Coordinate Measuring Machine

- 2.5-D Projector

- Optical Comparator

- Contour Measuring Instrument

- Surface Roughness & Height Test Machines

- Ultrasonic Test Equipment

- Air Leak Test Machine

- Salt Spray Test Machine

- ISO Certificates