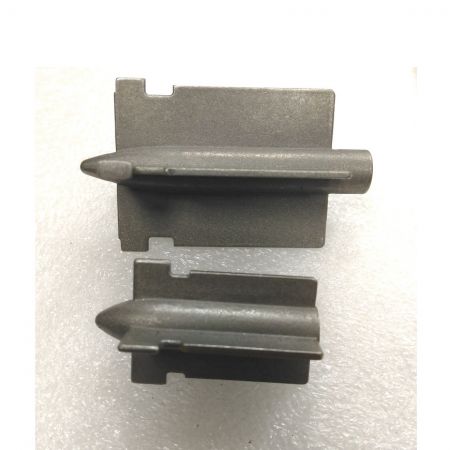

Carbon Steel Castings

Custom Carbon Steel Castings

Teamco produces custom steel castings in carbon steels for many industrial applications such as oil&gas, fluid control, petrochemical, energy, electrical, machinery, automotive, automation equipment, etc. More than 55% of our steel castings are in carbon steel and its alloy. Some customer designs require specific operations or treatments, such as heat treatment, grinding, plating or coating, etc. Teamco is capable of providing complete and competitive solutions. We produce OEM carbon steel castings. All our engineering, quality and sales team evaluate how to achieve customer specifications based on manufacturing capability, machining equipment, supply chain resources and long-term material supply, etc.

Through full communication with the customer, we build up working model beneficial to customer’s competitive advantages. Carbon steel is readily available in numerous grades and can be heat-treated to improve strength, ductility, and machinability. According to the carbon contents, carbon steels can be classified as low-carbon steels, mid-carbon steels and high-carbon steels. Our main castings are in WCC, WCB, LCC and LCB carbon steels. Except considering the applications, some properties are also factors for selection, such as machinability, ductility, weldability, strength requirements, formability, wear resistance, and corrosion resistance, etc. We provide various material grades fit customer’s requirements.

- Part size we produce: Investment casting - 300 x 300 x 270mm

- Part weight we produce: Investment casting – 10g ~ 30Kgs

- Material Grades we produce: WCC, WCB, LCC, LCB

- Mechanical Properties: strength, toughness, ductility, weldability and durability, etc.

Production Procedures of Investment Casting (Lost-Wax Casting):

Tooling Die (tooling design and tooling making)

Wax Mold (wax injection and tree assembly)

Shell Mold (dipping & stuccoing, drying and de-wax)

Pouring (shell mold sintering and metal liquid pouring)

Casting (air cooling, shake out, cutting, ingate grinding and sand blasting)

Subsequent Operations and Treatments

- Heat treatment (nitriding, normalization, quenching, tempering, etc.)

- Machining (high precision machining including turning, milling, drilling, tapping, broaching, etc.)

- Surface Grinding or Polishing (plus plating or coating for corrosion resistance)

- Plating (zinc, nickel, chrome plating, etc.)

- Coating (zinc phosphating, thermal spraying and MoS2 coating, etc.)

Applications

- Energy: oil&gas (midstream), petrochemical

- Fluid Control: flow control, food process, chemical process, pumping

- Engineering: automation equipment

- Machinery: mechanical equipment, hand tools, machining tool components

- Automotive: system components and accessories

- Construction: building hardware, locking components

- Others: electronics components, boat equipment metal parts

Purchase Information

- L/T (Lead Time for Samples and Mass Production): please confirm with contact sales for the best shipping schedule.

- MOQ (Minimum Order Quantity): depending on design and specifications (to be confirmed)

- MTR (Material Test Report): Mill Certificate + Inspection Report + Others Per Customer’s Requests (to be confirmed)

- Shipping Term: FOB

- For specific custom requirements such as special designs, inspection standards or materials, please contact our sales representatives for further details.

- Gallery

- Related Products

Steel Fluid Control Measuring Parts

With a comprehensive portfolio of in-house services and resource integration capability, Teamco...

DetailsAlloy Steel Castings

Teamco produce alloy steel castings according to customer designs when applications require...

DetailsPrecision Machining Valve Accessories

We offer comprehensive single-source capability and serve as a one-stop shop, taking customer's...

Details- DM Download

Carbon Steel Castings | Advanced Grease Fittings and Valve Accessories: Ensuring Reliability Under Pressure

Located in Taiwan since 1995, Teamco Industries Corporation specializes in manufacturing Carbon Steel Castings, precision machined valve components, custom metal parts for sensors and controls, high-pressure grease fittings and valve accessories, stainless steel and alloy-based parts for various industrial applications and comprehensive assembly services for cable and wiring harnesses. Discover top-tier precision machined valve components tailored for demanding industrial applications. Teamco specializes in custom solutions for oil, gas, and beyond, ensuring unparalleled quality and performance.

Teamco is a leading manufacturer specializing in high-quality machined metal parts, catering to critical industries like Oil & Gas. With a focus on precision and reliability, our product range includes CF8M Casting Ball Valve Parts, Stainless Steel Machined Valve Components, and High Pressure Grease Fittings, among others. Our commitment to excellence is backed by robust OEM capabilities and a comprehensive approach to metal parts assembly, ensuring top-tier performance and durability for industrial and marine applications.

Teamco has been offering customers high-pressure grease fittings and valve accessories to clients, both with advanced technology and 30 years of experience, Teamco ensures each customer's demands are met.