Custom Wave Spring

Custom Wave Spring fits Diversified Applications

Specializing in producing wave springs used in oil & gas valve assembly parts, Teamco also has extended our applications to mechanical seal, solenoid valves, gear box, construction structural assembly fasteners and optical mechanics. Teamco provides custom wave springs in single and multi-wave configurations. The produced material range includes Inconel X750, 718, 625, Stainless Steel, Carbon Steel and Other Alloys. Except the material selection, spring size and surface finish can also be customized according to specific applications. We have in-house tooling design center conducts computer aided spring calculations for each custom design so we are capable of providing OEM, ODM services and technical supports.

We are proud of our unique process and vast experiences in diversified materials which allow us to manufacturer high quality and high temperature resistant wave springs in custom specifications. Diameter size ranges from 1/2” to 16” (12mm~500mm). Two major types are single turn and multi turn. Our wave springs fit many industries such as Oil & Gas, Mechanical Machining, Electronics, Constructions, Hydraulics and Power Industry. When receive customer request, our service team will evaluate how to achieve the required specifications.

Wave Springs in Specifications fit Customer Applications

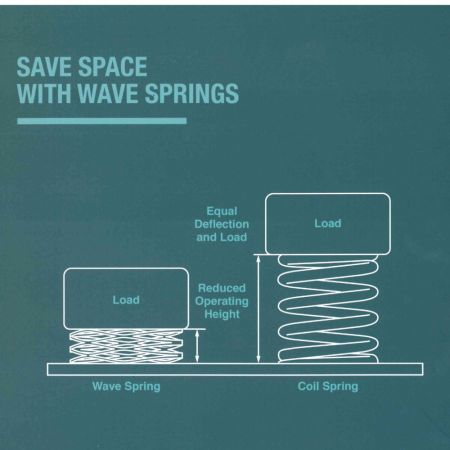

Wave spring is a type of compression spring made from pre-hardened flat wire in a process called on-edge coiling (or edge-winding) with waves added along the coils for more spring effect. They are suitable for applications that have minimal space but need tight load deflection. The axial space can be reduced up to 50%. Spring steels are mostly low-alloy manganese, low carbon steel or high carbon steel with very high yield strength, stainless steel and special alloys for high corrosion resistance or very high temperature applications. More information, specifications and details of our custom services can be found below.

Our ODM Services – Extensive From Design To Manufacturing And Test

Wave spring is a type of compression spring made from pre-hardened flat wire, coiling with waves to obtain spring effect. They are suitable for applications that have minimal space but need tight load deflection. The axial space can be reduced up to 50%. Spring steels are mostly low-alloy manganese, low carbon steel or high carbon steel with very high yield strength, stainless steel and special alloys for high corrosion resistance or very high temperature applications.

Features:

Space Savings:Reduced work height. Up to 50% of Axial Space savings compared to conventional coil springs

Spring Characteristics:Precise specification of the spring load at individual work heights

Flexible Flat Wire Production:1. In-house flat wire production for various dimensions. 2. Special grades available. 3.Prototypes and large production runs

Quality:1. Certified to ISO 9001. 2.Spring Fatigue Cycle Test. 3. Loading Test

ODM Procedures

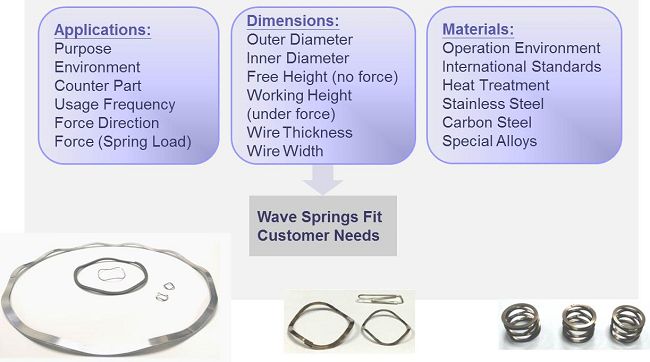

Clarifying Requirements

- Applications

- Dimensions

- Materials

Engineering Designing

- Wire Specifications

- Material Specifications

- Heat Treatment

- Spring Force

- Spring Type

- Equipment

Forming to Custom Springs

- Rolling round wire to flat wire

- Heat treatment

Teamco Can Design Wave Springs Fit Customer’s Applications.

Specification:

| Size Range: | Types: | Applications |

|---|---|---|

| 1/2" ~ 16" (12mm ~ 500mm) | ● Single Turn ● Nested Multi Turn ● Multi Turn | ● Oil & Gas ● Mechanical Sealing ● Construction ● Hydraulics ● Solenoid Valves ● Gear Pumps ● Automotive ● Aerospace |

Standard Material Grades

| Carbon Steel US Designation (DIN) | Stainless Steel US Designation (DIN) |

|---|---|

| AISI 1070~1090 (1.1231~1.1273) | 17-7PH (1.4568~ X7CrNiAl 17-7) |

| 302 & 304 & 316 (1.4319 & 1.4301 & 1.4401) |

Special Material Grades

| US Designation (DIN) | US Designation (DIN) |

|---|---|

| Inconel X-750 & 718 & 625 (2.4669 & 2.4668 & 2.4856) | Beryllium Copper (2.1247) |

| Incoloy A-286 (1.4980) | Elgiloy (2.4711) |

| Hastelloy B-2 & B-3 & C-22 & C-276 & C-2000 (2.4617 & 2.4600 & 2.4602 & 2.4819 & 2.4675) | Haynes 214 (2.4646) |

| Alloy 20 CB3 (2.4660) | MP35N (2.4999) |

| Monel K-500 (2.4375) | Nimonic 90 & 80A (2.4969 & 2.4631) |

| Rene 41 (2.4973) | Nickel 270 |

Purchase Information

- L/T (Lead Time for Samples and Mass Production): please confirm with contact sales for the best shipping schedule.

- MOQ (Minimum Order Quantity): depending on design and specifications (to be confirmed)

- MTR (Material Test Report): Mill Certificate + Inspection Report + Others Per Customer’s Requests (to be confirmed)

- Shipping Term: FOB

- For specific custom requirements such as special designs, inspection standards or materials, please contact our sales representatives for further details.

- Gallery

- Related Products

Stainless Steel Castings

From prototype to full production, Teamco produces custom steel castings for wide variety of applications...

DetailsCompression Springs

Compression springs are open-coil helical springs that offers resistance to a compressive force...

Details- DM Download

Custom Wave Spring | Advanced Grease Fittings and Valve Accessories: Ensuring Reliability Under Pressure

Located in Taiwan since 1995, Teamco Industries Corporation specializes in manufacturing Custom Wave Spring, precision machined valve components, custom metal parts for sensors and controls, high-pressure grease fittings and valve accessories, stainless steel and alloy-based parts for various industrial applications and comprehensive assembly services for cable and wiring harnesses. Discover top-tier precision machined valve components tailored for demanding industrial applications. Teamco specializes in custom solutions for oil, gas, and beyond, ensuring unparalleled quality and performance.

Teamco is a leading manufacturer specializing in high-quality machined metal parts, catering to critical industries like Oil & Gas. With a focus on precision and reliability, our product range includes CF8M Casting Ball Valve Parts, Stainless Steel Machined Valve Components, and High Pressure Grease Fittings, among others. Our commitment to excellence is backed by robust OEM capabilities and a comprehensive approach to metal parts assembly, ensuring top-tier performance and durability for industrial and marine applications.

Teamco has been offering customers high-pressure grease fittings and valve accessories to clients, both with advanced technology and 30 years of experience, Teamco ensures each customer's demands are met.