Grease Fitting

Grease Fittings fits API Standards

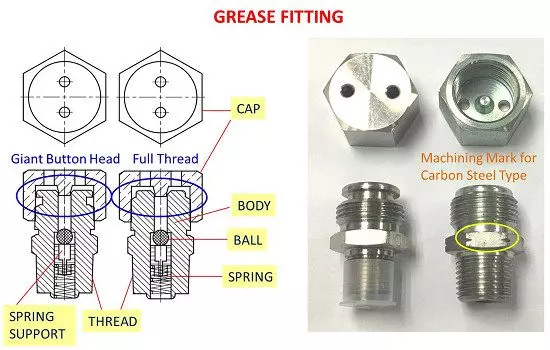

Grease fittings used for grease lubrication for valve pipelines repair and equipment maintenance have been our main sector in valve fittings. We produce grease fittings most in stainless steel 316 and carbon steel 4140 zinc plated, other alloys are also in our material range, depending on required mechanical strength and corrosion resistance level. Our grease fittings are designed to achieve API pressure class of 10,000psi. Main applications of our grease fittings include oil and gas valve lubrications and industrial fluid control equipment grease injection. There are two head types, the giant button head and the full thread type, usually equipped with vented cap to enhance the sealing function.

Our grease fittings apply to API applications. Virtually every valve with moving metallic parts needs lubrication. Lubricants help to reduce valve operating torque. Periodic maintenance makes valves operate easier and seal properly. Small amount of the correct lubricant into the body or seat rings, fresh grease into the stem bearings, checking the stem packing and refilling as necessary will add years to the service life of the valve. We export to worldwide industrial customers in USA, Canada, Italy and Malaysia, etc. ODM and OEM are services which make us a trustworthy partner for customers.

Specification:

End Connection Thread Type: NPT 1/2”, 1/4”, 3/8”, 3/4”, 1”, 1-1/2”

Material Type: Inconel, SS316, SS304, AISI 4140 Zinc Plated, A105

Head Type: Giant Button Head, Standard

Vented Cap: With/ Without Vented Cap

Standards: API 6A, 6C, 6D

Pressure Class: 5,000 ~ 20,000psi

Please refer to below table or “Spec. Chart” in below Tag “DM DOWNLOAD” for popular specifications we produce.

| Thread Size | Head Type | Body Material | Part Number |

|---|---|---|---|

| 1/4" NPT | Full Thread | 4140 Zinc Plating | GFFT14-414 |

| SS316 | GFFT14-316 | ||

| Giant Button Head | 4140 Zinc Plating | GFBH14-414 | |

| SS316 | GFBH14-316 | ||

| 3/8" NPT | Full Thread | 4140 Zinc Plating | GFFT38-414 |

| SS316 | GFFT38-316 | ||

| Giant Button Head | 4140 Zinc Plating | GFBH38-414 | |

| SS316 | GFBH38-316 | ||

| 1/2" NPT | Full Thread | 4140 Zinc Plating | GFFT12-414 |

| SS316 | GFFT12-316 | ||

| Giant Button Head | 4140 Zinc Plating | GFBH12-414 | |

| SS316 | GFBH12-316 | ||

| 3/4" NPT | Full Thread | 4140 Zinc Plating | GFFT34-414 |

| SS316 | GFFT34-316 | ||

| Giant Button Head | 4140 Zinc Plating | GFBH34-414 | |

| SS316 | GFBH34-316 | ||

| 1" NPT | Full Thread | 4140 Zinc Plating | GFFT11-414 |

| SS316 | GFFT11-316 | ||

| Giant Button Head | 4140 Zinc Plating | GFBH11-414 | |

| SS316 | GFBH11-316 |

Basic Construction

| Description | Material Grades (Custom Specifications) |

|---|---|

| 1. Body 2. Vented Cap 3. Ball 4. Spring 5. Spring Support | Body: Inconel X-750, SS316, SS304, 4140 Zinc Plated, A105 Ball: Tungsten Carbide, Inconel X-750, Monel K-500, SS316, SS304 Spring: Inconel X-750, SS316, SS304 |

Our ODM Services – Design, Manufacture and Test to fit Customer Applications

Please provide us your requirements, our in-house engineering team will design or recommend the right grease fitting fits your needs.

- Main application

- Pressure class

- Material

- Thread type and size

Applications

- Oil & Gas Valve Pipeline

- Wellheads

- Petrochemical

- Refinery

- Industrial Mechanical System

Purchase Information

- L/T (Lead Time for Samples and Mass Production): please confirm with contact sales for the best shipping schedule.

- MOQ (Minimum Order Quantity): depending on design and specifications (to be confirmed)

- MTR (Material Test Report): Mill Certificate + Inspection Report + Others Per Customer’s Requests (to be confirmed)

- Shipping Term: FOB

- For specific custom requirements such as special designs, inspection standards or materials, please contact our sales representatives for further details.

- Related Products

High Pressure Grease Fitting

To fit specifically high pressure application, Teamco provides high pressure grease achieve...

DetailsPressure Relief Valve

Pressure relief valve is one of our valve fitting types performs as a safety mechanism to prevent...

DetailsLeak Lock Fitting

The leak lock fittings can be utilized to block the leaking valves or inject lubricants or sealants...

Details- DM Download

Grease Fitting | Advanced Grease Fittings and Valve Accessories: Ensuring Reliability Under Pressure

Located in Taiwan since 1995, Teamco Industries Corporation specializes in manufacturing Grease Fitting, precision machined valve components, custom metal parts for sensors and controls, high-pressure grease fittings and valve accessories, stainless steel and alloy-based parts for various industrial applications and comprehensive assembly services for cable and wiring harnesses. Discover top-tier precision machined valve components tailored for demanding industrial applications. Teamco specializes in custom solutions for oil, gas, and beyond, ensuring unparalleled quality and performance.

Teamco is a leading manufacturer specializing in high-quality machined metal parts, catering to critical industries like Oil & Gas. With a focus on precision and reliability, our product range includes CF8M Casting Ball Valve Parts, Stainless Steel Machined Valve Components, and High Pressure Grease Fittings, among others. Our commitment to excellence is backed by robust OEM capabilities and a comprehensive approach to metal parts assembly, ensuring top-tier performance and durability for industrial and marine applications.

Teamco has been offering customers high-pressure grease fittings and valve accessories to clients, both with advanced technology and 30 years of experience, Teamco ensures each customer's demands are met.