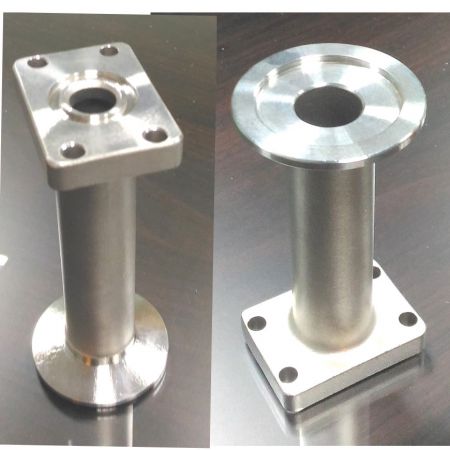

Steel Fluid Control Measuring Parts

Machined Custom Flow Control Components

With a comprehensive portfolio of in-house services and resource integration capability, Teamco is a one-stop shop producer with high engineering support. We produces precision machined metal parts for fluid control or pressure measuring application. These components always require multiple production procedures, such as heat treatments or surface coatings, etc. Items include flowmeter body, conduit adapter, rotor, vane, union, tube sleeves, etc.

Stainless Steel is the major material we provide, material grade is based on customer designs. We produce these parts in investment casting or bar stock machining. We also provide sub assembly services for the customer. All our services are customized. We serve customers from various segments include oil&gas, petrochemical, automation, automotive, fluid process and control, etc.

Precision Machining Fluid Control Measuring Parts We Produce:

Part Names: Flowmeter Body, Conduit Adapter, Rotor, Vane, Bearing Support, Tube Sleeve, Fittings, etc.

Flow Way Size: 1/2” ~ 4”

Pressure Class: #150 ~ #2500

Our Machining Capability:

Raw Materials: Castings, Bar Stocks, etc.

Part Weight: 10g~40Kgs

Part Size: 1M max.

Materials:

- Stainless Steel – CF3M, CF8M, 304, 316, 316/ 316L Dual, Duplex Stainless Steel CD4MCU

- Carbon Steel – WCB, WCC, LCB, LCC, 4140

Machining Equipment:

- CNC Lathe & CNC Milling

- Horizontal Machining Center & Vertical Machining Center

- Traditional Lathe

- Vertical Drilling Machine & Radial Drilling Machine

Applications

- Oil&Gas Pipeline Operation

- Oil&Gas Transporting and Storing

- Liquid Processing

- Gas Transmission

Purchase Information

- L/T (Lead Time for Samples and Mass Production): please confirm with contact sales for the best shipping schedule.

- MOQ (Minimum Order Quantity): depending on design and specifications (to be confirmed)

- MTR (Material Test Report): Mill Certificate + Inspection Report + Others Per Customer’s Requests (to be confirmed)

- Shipping Term: FOB

- For specific custom requirements such as special designs, inspection standards or materials, please contact our sales representatives for further details.

- Gallery

- Custom Propeller Flow Meter Parts

- Custom Flowmeter Body 316/316L

- Custom Flowmeter Body and Adapter

- Meter Part Stainless Steel

- Meter Adapter Stainless Steel

- Custom Meter Part Stainless Steel

- Cartridge CF8M

- Rotors Duplex Stainless Steel CD4MCU

- Custom Flowmeter Parts

- Custom Conduit Union Parts

- Custom Conduit Union Kit Parts

- Stainless Steel Fluid Control Parts

- Tube CF8M

- Casting Sleeves Stainless Steel

- Stainless Steel Gas Tube

- Custom Fluid Control Fittings

- Related Products

Custom Choke Valve Parts for Flow Control

With long experiences in achieving customer’s design specifications and quality inspections,...

DetailsStainless Steel Castings

From prototype to full production, Teamco produces custom steel castings for wide variety of applications...

DetailsPrecision Machining Valve Accessories

We offer comprehensive single-source capability and serve as a one-stop shop, taking customer's...

Details

Steel Fluid Control Measuring Parts | Advanced Grease Fittings and Valve Accessories: Ensuring Reliability Under Pressure

Located in Taiwan since 1995, Teamco Industries Corporation specializes in manufacturing Steel Fluid Control Measuring Parts, precision machined valve components, custom metal parts for sensors and controls, high-pressure grease fittings and valve accessories, stainless steel and alloy-based parts for various industrial applications and comprehensive assembly services for cable and wiring harnesses. Discover top-tier precision machined valve components tailored for demanding industrial applications. Teamco specializes in custom solutions for oil, gas, and beyond, ensuring unparalleled quality and performance.

Teamco is a leading manufacturer specializing in high-quality machined metal parts, catering to critical industries like Oil & Gas. With a focus on precision and reliability, our product range includes CF8M Casting Ball Valve Parts, Stainless Steel Machined Valve Components, and High Pressure Grease Fittings, among others. Our commitment to excellence is backed by robust OEM capabilities and a comprehensive approach to metal parts assembly, ensuring top-tier performance and durability for industrial and marine applications.

Teamco has been offering customers high-pressure grease fittings and valve accessories to clients, both with advanced technology and 30 years of experience, Teamco ensures each customer's demands are met.