Extension Springs

Extension Springs According to Customer's Applications

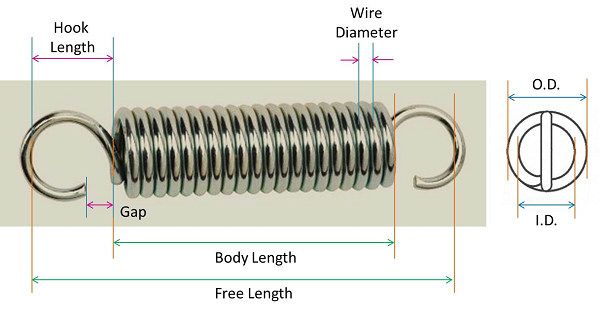

Extension springs are used when extension force is required. Teamco manufactures custom extension springs from multiple types of material such as music wire, hard drawn, stainless steel, oil tempered, Inconel, Monel, beryllium copper, etc. The extension springs absorb and store energy as well as create resistance to a pulling force between two opposing components. They are made from different types of wires and are tightly coiled. They stretch when bearing force. Teamco provides spring ends in hook or loop configurations fit customer’s assembly functions. The most common ends are the machine loop and crossover loop. Our extension springs and services are tailor-made and produced according to international standards.

The applications include automotive, mechanical equipment, sportive equipment, medical devices, etc. It starts to deform when the extension force is greater than the compression force. This corresponded tensile load is the initial tensile force which depends on material types, diameter, spring winding ratio and the processing method, which also determines how tightly together the spring needs to be coiled during the manufacturing process. All production follows customer required specifications. We export our extension springs to various industrial customers in Europe, Asia, and America.

Extension Spring Ends:

Machined Hooks/ Loops

Crossover Center Hooks/ Loops

Side Hooks/ Loops

Eye Shaped Ends

Rectangular Ends

Threaded Plug Types

U Hook/ V Hook Ends

Standard Material Grades

| Carbon Steel US Designation (DIN) |

Stainless Steel US Designation (DIN) |

|---|---|

| AISI 1070~1090 (1.1231~1.1273) | 17-7PH (1.4568~ X7CrNiAl 17-7) |

| 302 & 304 & 316 (1.4319 & 1.4301 & 1.4401) |

Special Material Grades

| US Designation (DIN) | US Designation (DIN) |

|---|---|

| Inconel X-750 & 718 & 625 (2.4669 & 2.4668 & 2.4856) | Beryllium Copper (2.1247) |

| Incoloy A-286 (1.4980) | Elgiloy (2.4711) |

| Hastelloy B-2 & B-3 & C-22 & C-276 & C-2000 (2.4617 & 2.4600 & 2.4602 & 2.4819 & 2.4675) |

Haynes 214 (2.4646) |

| Alloy 20 CB3 (2.4660) | MP35N (2.4999) |

| Monel K-500 (2.4375) | Nimonic 90 & 80A (2.4969 & 2.4631) |

| Rene 41 (2.4973) | Nickel 270 |

Our ODM Services – Extensive from Design to Manufacturing and Test

Teamco offers a wide range of custom spring capabilities, design options and extensive material and finish selections. Please provide us below information, and let us know your application, our engineering team will design the springs fit your requirements.

- Spring OD/ ID

- Working Height

- Free Height

- Solid Height

- Wire Diameter

- Wire Pitch

- Material

Extension Springs in Customer Required Specifications and Materials.

Applications

- Automotive

- Machinery

- Garage Doors

- Sportive Equipment

- Farm Equipment

- Medical Devices

- Hand Tools

Purchase Information

- L/T (Lead Time for Samples and Mass Production): please confirm with contact sales for the best shipping schedule.

- MOQ (Minimum Order Quantity): depending on design and specifications (to be confirmed)

- MTR (Material Test Report): Mill Certificate + Inspection Report + Others Per Customer’s Requests (to be confirmed)

- Shipping Term: FOB

- For specific custom requirements such as special designs, inspection standards or materials, please contact our sales representatives for further details.

- Related Products

-

Compression Springs

Compression springs are open-coil helical springs that offers resistance to a compressive force...

DetailsCustom Wave Spring

Specializing in producing wave springs used in oil & gas valve assembly parts, Teamco also...

DetailsPrecision Machining Valve Accessories

We offer comprehensive single-source capability and serve as a one-stop shop, taking customer's...

Details

Extension Springs | Advanced Grease Fittings and Valve Accessories: Ensuring Reliability Under Pressure

Located in Taiwan since 1995, Teamco Industries Corporation specializes in manufacturing Extension Springs, precision machined valve components, custom metal parts for sensors and controls, high-pressure grease fittings and valve accessories, stainless steel and alloy-based parts for various industrial applications and comprehensive assembly services for cable and wiring harnesses. Discover top-tier precision machined valve components tailored for demanding industrial applications. Teamco specializes in custom solutions for oil, gas, and beyond, ensuring unparalleled quality and performance.

Teamco is a leading manufacturer specializing in high-quality machined metal parts, catering to critical industries like Oil & Gas. With a focus on precision and reliability, our product range includes CF8M Casting Ball Valve Parts, Stainless Steel Machined Valve Components, and High Pressure Grease Fittings, among others. Our commitment to excellence is backed by robust OEM capabilities and a comprehensive approach to metal parts assembly, ensuring top-tier performance and durability for industrial and marine applications.

Teamco has been offering customers high-pressure grease fittings and valve accessories to clients, both with advanced technology and 30 years of experience, Teamco ensures each customer's demands are met.