Casting Mold Tooling Design Optimization Improves Sample Lead Time

Mold Flow Simulation Software Improves Sample Sending Efficiency

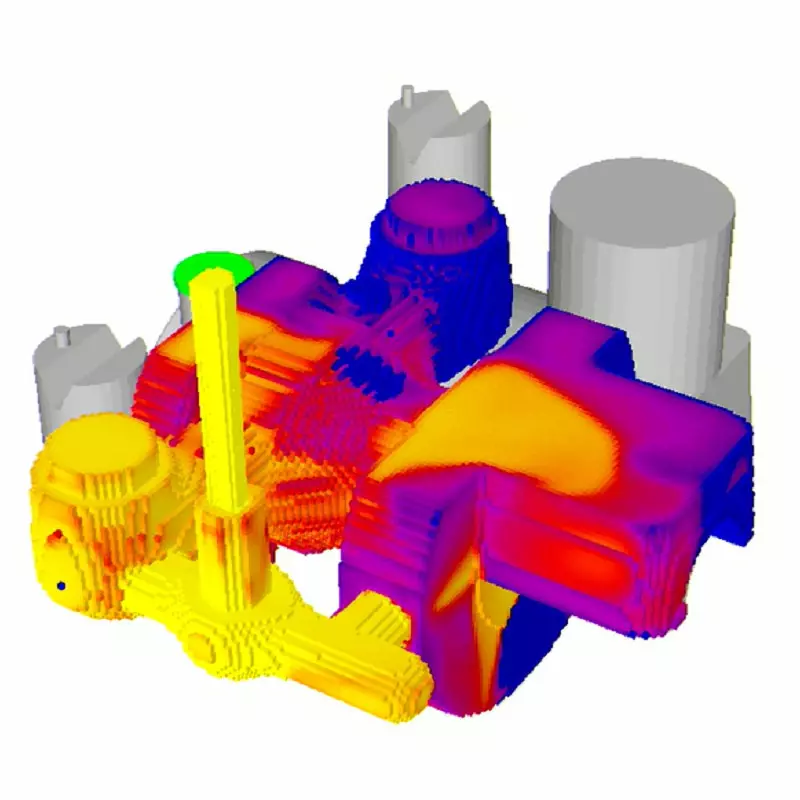

With own engineering team capable of designing casting tooling pattern, Teamco knows how to achieve customer’s specifications. Before, tooling pattern design was done by CAD software. There was no effective way to verify result of the design. When new product development schedule became more critical for worldwide customers, we had to improve our design and sample quality to remain competitiveness. Investing in the Mold Flow Simulation Software had helped greatly realizing the sample quality and schedule through optimizing the tooling design. Customers are satisfied with quality of our products and services.

| Case: | Casting Mold Tooling Design Optimization Improves Sample Lead Time |

|---|---|

| Customer Country: | Worldwide |

| Application: | Oil & Gas, Flow Control, Liquid Processing, Power Plant Equipment, etc. |

| Product Name: | Ball Valve Body/Cap, Gate Valve Body, Piston Check Valve Body, Butterfly Valve Body |

| Production: | Sand Casting, Investment Casting |

| Tool: | Mold Flow Simulation Software |

Customer Requirement

Sand casting has been our core business for more than 20 years. Teamco has vast experiences developing many designs with customers, especially the Oil & Gas segment. Tooling design for new sand casting product takes long time and the genuine feature of porosity issue causes necessity of tooling modification; this impacts yield result and eventually the sample lead time. The top priority lies in casting quality which brings to functional safety in customer applications.

Technical Issues or Challenges

In traditional way when designing the tooling pattern, situations of various metal liquid flows proceeding in the gateway system differ and some potential defects could not be foreseen and then prevented. Therefore it needs several times of tooling modification. This influences quality of the sample castings and the production schedule, also influences competitiveness of Teamco and our customers.

Teamco Solution

Our engineering team decided to apply software to simulate the mold flow, predict potential defects, fine tune and then optimize the tool design. This saves times of tooling modification and helps in obtaining the best quality casting with the best cost. Eventually the sample sending efficiency and result improved and customer is satisfied with our services for new product development.

Customer Benefits

•Improve product quality and lead time.

•Customers trust more our capability because we understand more their designs and requirements.

•Increase customer satisfaction on Teamco castings; help remain customer competitiveness.